energy recovery devices

Turbocharger Energy Recovery Devices

-

Min flow: 13 gpm

-

Max flow: 13,200 gpm

-

Up to 1,800 psi

-

Super Duplex construction

- Min flow: 2,200 gpm

- Max flow: 13,200 gpm

- Up to 1,200 psi

- Super Duplex construction

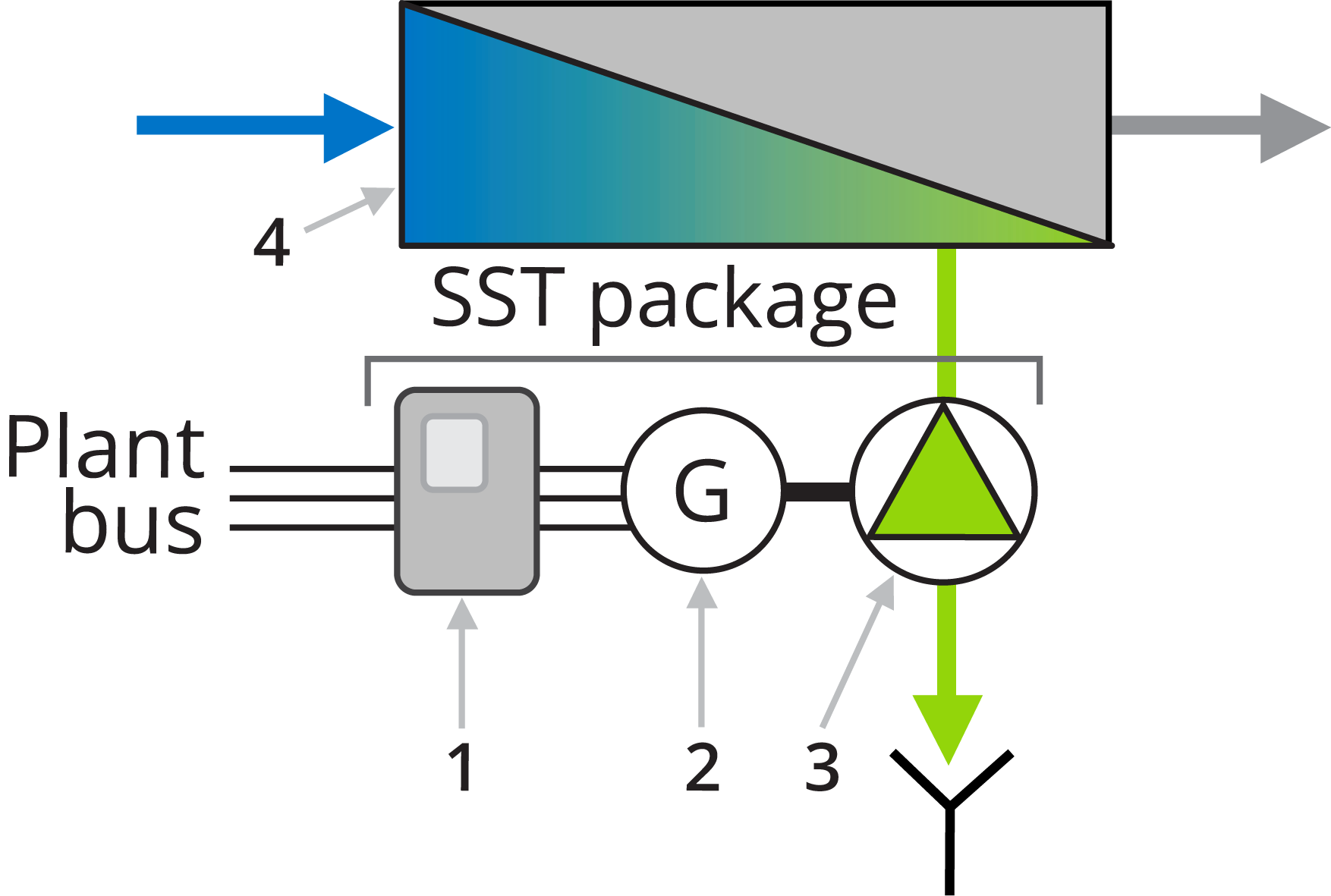

Turbo-Generators

-

Min flow: 220 gpm

-

Max flow: 1,540 gpm

-

Up to 130 psi

-

Super Duplex construction

- Regen VFD (optional)

- Generator

- Turbine

- RO/NF membrane

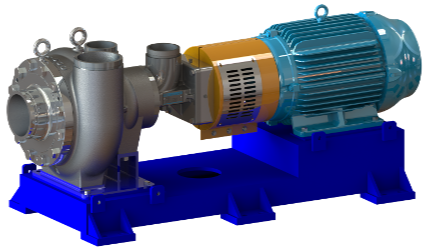

Pumps Designed

for the

Most Demanding Conditions

- Duplex or Super Duplex Materials of Construction

- Exclusive WATER BEARINGTM for exceptional reliability

- ROTOR-FLOTM turbo lubrication system

- All pumps performance tested

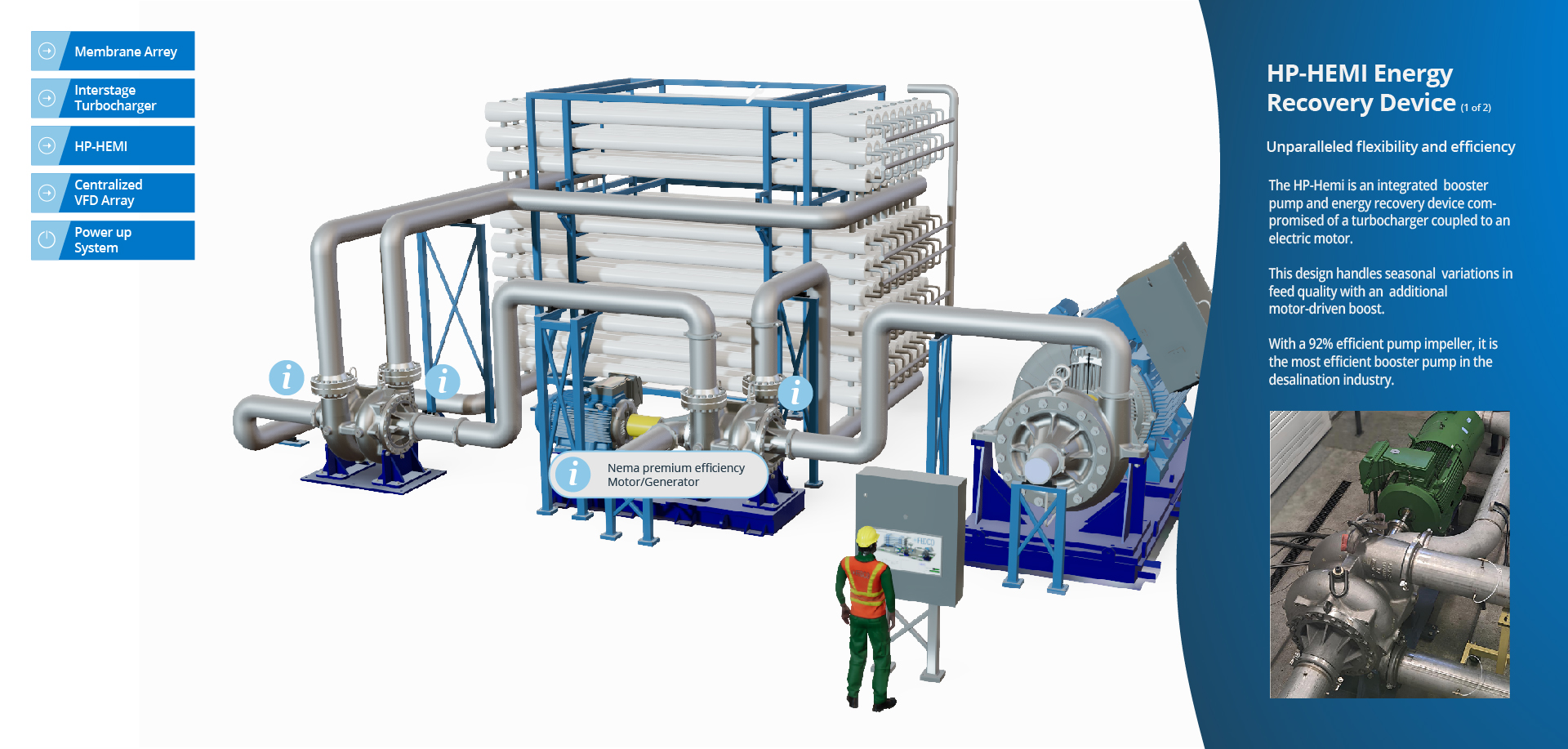

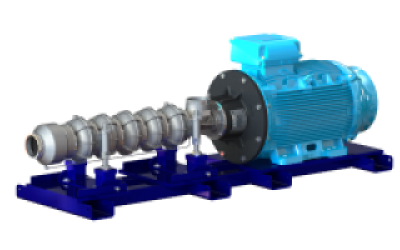

HP-HEMI Motorized

Turbocharger

- Min flow: 500 m3/hr

- Max flow: 3,000 m3/hr

- Pressures to 83 bar (1200 psi)

- Super Duplex construction

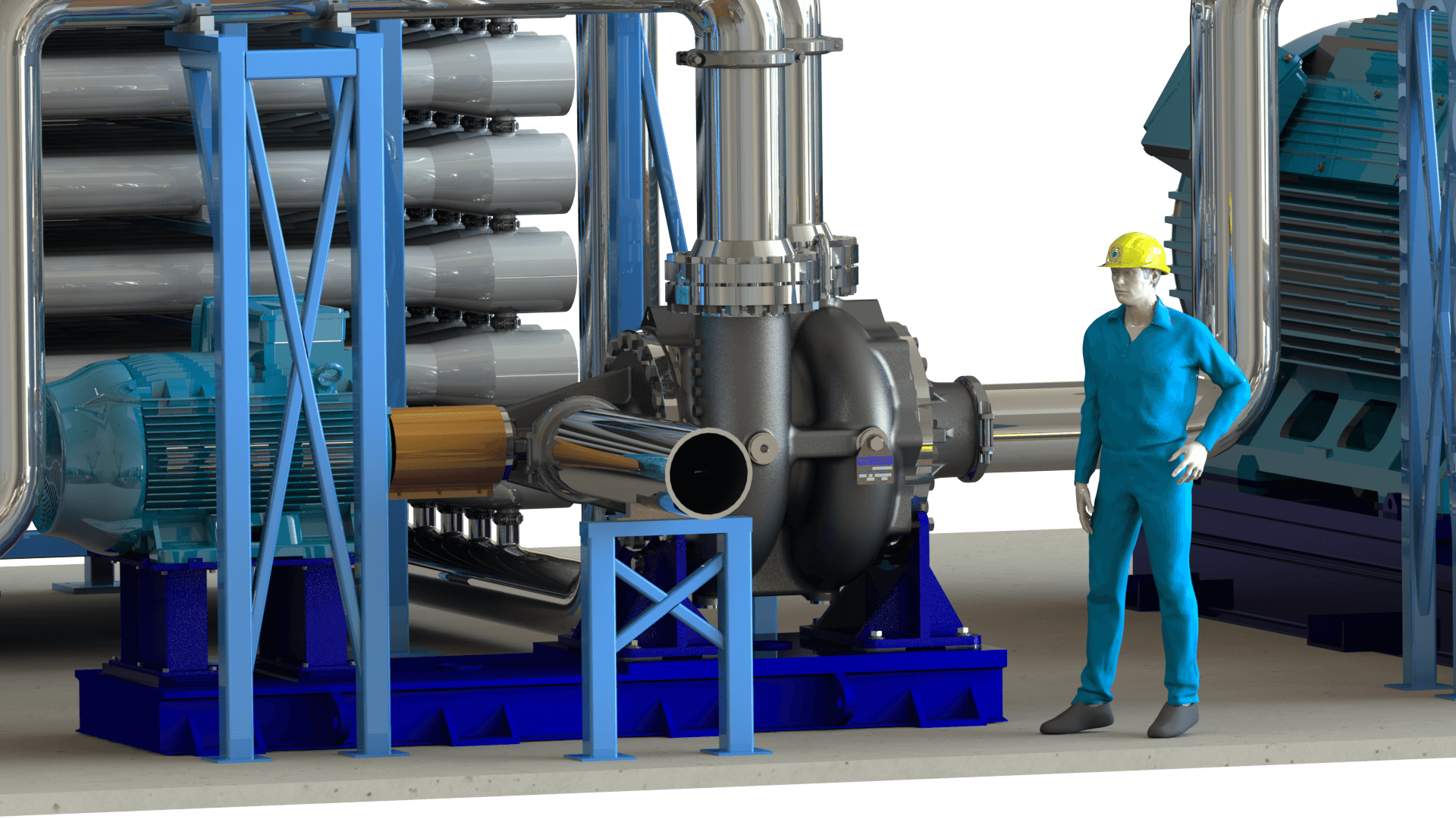

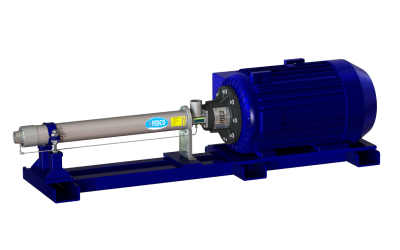

Turbochargers harness brine energy to pressurize a reverse osmosis feed stream, reducing energy consumption and equipment requirements.

In a turbocharger, high-pressure brine flow drives a turbine, which is connected by a one-piece rotor to a pump impeller.

This efficiently transfers energy from a pressurized brine stream into a feed pressure boost with close to zero noise and vibration.

Turbochargers are an all-in-one energy recovery solution and require no motors, drives, lubrication lines or manifolds.

Turbochargers can be installed directly after the high-pressure feed pump, or in place of an interstage booster pump.

This reduces the pressure required from the high-pressure feed pump, reducing its size and motor speed.

Optimize pressure management for large-scale SWRO and BWRO systems.

The HP-HEMI motorized turbocharger is designed for situations where brine energy alone is insufficient to provide the necessary boost.

The HP-HEMI consists of a turbocharger coupled to a motor, meaning that a VFD can be used to increase feed pressure boost by modifying the rotor speed.

This solution keeps energy consumption low, as most of the pressure boost is powered by brine energy, with the motor supplementing the boost as needed.

The HP-HEMI is the latest generation of FEDCO products that combine brine energy and electrical power.

FEDCO's motor-assisted turbochargers have been successfully deployed in California and Singapore, in some of the world's largest wastewater reuse facilities.

From mega-scale desalination to containerized and offshore systems, turbochargers power thousands of reverse osmosis installations worldwide.

FEDCO’s Hydraulic Pressure Boosters or HPB energy recovery turbocharger leads the industry in efficiency and reliability. The HPB™ turbocharger reduces the energy consumed in a seawater RO system by up to 50%. With the HPB™, you can recover more than 80% of the wasted high pressure brine energy to reduce the size of the high pressure feed pump, lowering the motor electrical consumption.

MSD Series

High Pressure Pump

- 20 – 1,080 m3/h (88 – 4755 gpm)

- Pressures to 83 bar (1200 psi)

- Super Duplex (Zeron-100) construction

- Maintenance and contaminant free Water BearingTM

MSD Series

High Pressure Pump

- 20 – 1,080 m3/h (88 – 4755 gpm)

- Pressures to 83 bar (1200 psi)

- Super Duplex (Zeron-100) construction

- Maintenance and contaminant free Water BearingTM

MSS Series High Pressure Pump

- 7.5 – 295 m3/h (33 – 1300 gpm)

- Pressures to 83 bar (1200 psi)

- 316L SS construction

- Maintenance and contaminant free Water BearingTM

SLP Feed Pump

- 6.8 – 375 m3/h (30 – 1650 gpm) feed flow

- Pressures from 2.4 – 9 bar (35 – 130 psi)

- Super Duplex construction

- High Efficiency

Reverse Osmosis

Our patented BiTurboTM desalination solution delivers optimal performance for any SWRO system by HPB turbochargers for both feed and interstage boosting.

Extend membrane life, improve permeate quality, and achieve recovery rates of 40-60% using conventional desalination equipment.

The HPB Energy Recovery Turbocharger increases performance and reduces operating costs when added to the MSS or MSD Series pumps.

It can also be used as an interstage booster to improve membrane performance and improve system reliability.

.png)